On 24th February 2023, an American customer sent us an inquiry. The name of his company is McGill Compost. McGill Compost is a reputable company in the U.S. and has been established for over 30 years. They told us that their company owned many industrial composting facilities in the eastern U.S.

In fact, they mainly sold bulk compost (roughly screened). After seeing the post on MFP’s organic fertilizer plant cost, they planned to make granular compost. Next, let’s see how we helped them pelletize their compost.

How we design a 40,000 tons per year Pelletizing Line for our USA Client?

They told us that their raw materials are compost. Besides, they got 40,000 tons per year of compost per location and they have five locations in total.

For a 40,000-ton granular organic fertilizer production line, it will produce about 3333 tons per month. Our client told us they have a one-shift system. After making careful calculations, we can determine that they need a compost granulator with a capacity of 16 tons per hour.

Therefore, MFP suggested that they can choose a drum granulator, which has a large capacity and can satisfy their needs.

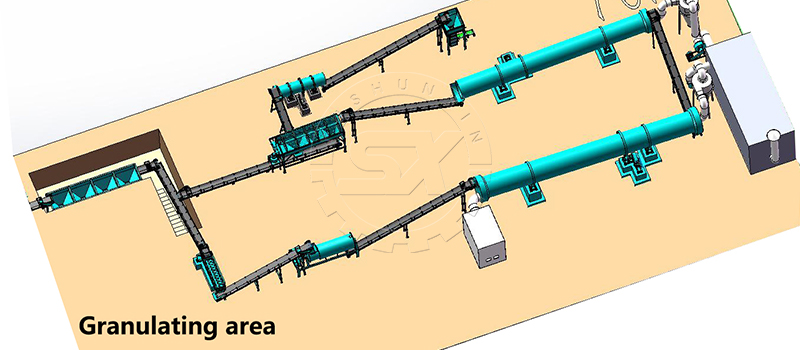

Considering the capacity and their budget, we recommended the drum granulation line for them. The standard configuration is a semi-wet material pulverizer, horizontal mixer, drum granulator, rotary drying machine, cooler, drum screening machine, automatic packaging equipment, and belt conveyors.

How does our Drum granulation line work for our U.S. Client?

Drum granulator is suitable for large-capacity granulating and is the perfect choice for McGill Compost company.

The diameter and body length of drum granulator determine its granulating efficiency and capacity.

Fortunately, MFP factory can customize the drum granulator. Therefore, we customize a drum granulator with a 16 t/h capacity and can well meet their needs.

MFP factory designs this drum granulator combined with existing experience and advanced technology on the market.

We use rubber plastics as the lining, thus greatly avoid raw materials sticking to the cylinder. More importantly, the lining inside the rotary drum granulator plays the role of anti-corrosion and heat preservation.

Auxiliary Equipment our American client choose in 16t/h production line

This client mentioned that they have been selling bulk and mostly screened to 3/8 minus compost. Considering the size of their raw materials, we designed his granulation line with a semi-wet compost crusher.

This type of crusher is designed to crush compost. It adopts double rotors and can crush materials with high-speed rotating blades.

Moreover, it can crush materials into 50 mesh. Then the rotary drum screener can get rid of impurities in the compost powder. Till now, the powder is ready for making pellets.

After granulating, it is necessary to remove the moisture between pellets. Because drum granulator uses agglomeration to form pellets by adding water. Therefore, reducing its moisture to prevent them from sticking and to convenient storage. Then, automatic packaging can pack compost pellets and belt conveyors can help with transmission.

Get a Quote

Besides pelletizing line, MFP factory can also assemble your NPK fertilizer production line and other organic fertilizer production line.

What’s more, we also manufacture livestock and poultry manure compost turners.

If you intend to produce fertilizer, welcome to send an inquiry to us!

Leave A Comment