Organic fertilizers have gained significant popularity in recent years, as more and more individuals and agricultural businesses recognize the benefits of environmentally friendly and sustainable farming practices. However, starting a successful organic fertilizer business requires careful consideration of various factors, including the initial investment required. In this page, we will explore the costs associated with establishing an organic fertilizer production venture, including the expenses related to raw materials, setting up a fertilizer factory, and acquiring the necessary machinery for efficient and effective fertilizer production. Additionally, we will delve into the potential profit margins of organic fertilizer manufacturing, providing valuable insights for aspiring entrepreneurs in this industry.

cost of raw materials in organic fertilizer production

Organic fertilizer production relies on a diverse range of natural ingredients, and the price of raw materials is also different.

For a poultry or livestock farmer, the fertilizer business is a good way to recycle waste and make a fortune. The ratio of raw materials to finished fertilizer pellets is three to one. That is to say, if you own a farm that can produce 30 tons of animal manure, you can get 10 tons of fertilizer. Therefore, making organic fertilizer can bring you additional profits if you own a poultry or livestock farm. Excluding the construction of rainproof steel structure greenhouses, organic fertilizer raw materials, and workers’ wages, you can make the money back in 4 to 6 months and get the profit in half a year. The return is generous, and the profit is considerable.

If you are interested in initiating an organic fertilizer business, there are two main options available to you. Firstly, you can gather farm manure from local farms or alternatively, purchase raw materials from the market. It’s worth noting that the cost of poultry manure varies depending on the season. This year, during spring, the price of animal manure per ton price ranged between $23 and $25, with a peak of $32. Currently, organic fertilizer pellets are being sold at a market price of $4.85 for a 50kg bag, which roughly amounts to $96.6 per ton. Consequently, by considering these figures, you can expect to generate a profit of approximately $60 per ton.

organic fertilizer factory Investment

Before setting up an organic fertilizer factory, you’d better conduct research. MFP specialists conclude four factors you need to consider. Before you begin construction or operation of the plant, you must obtain all necessary licenses and permits from the relevant authorities, such as leases of land and business license. What’s more, depending on the regulations in your area, you may need to obtain health and safety permits to ensure that your organic fertilizer plant is producing safe and healthy products.

- First, the factory should be near the farm, therefore you can transport animal manure in a convenient way. Also, it would be better if it’s near the sales area.

- Second, it should be far away from the water supply in case it pollutes water.

- Third, the site of the organic fertilizer factory should be convenient to transport.

- At last, you should build the fertilizer plant in a dry, flat, well-drained place, and the lowest level should be above the local flood line. Its groundwater level should be below 3 meters, such a situation can avoid the threat of flood in the rainy season.

organic fertilizers industry building cost

The organic fertilizer industry building cost depends on the configuration of the equipment. To mass produce organic fertilizer, you need enough space and platforms. First, if you adopt the aerobic fermentation method, you need to construct a factory and purchase deodorant equipment to meet environmental requirements. Then you need a complete production line of fertilizer machines to make organic fertilizer pellets and pack them. Farms need to set up a pretreatment field for livestock and poultry manure. The storage capacity of the manure should be determined by the amount of manure and the pretreatment capacity.

For example, the capacity of the manure pretreatment field with a scale of 1,000 cows should not be less than 500 m³, and it must be able to store solid manure produced by livestock and poultry manure for 15 to 20 days. For those who have newly invested in organic fertilizer equipment for the first time, an organic fertilizer production line with an annual output of 10,000 to 30,000 tons is enough.

The simple configuration occupies a small area, and the complete set of configurations occupies a large area. The simplest configuration equipment covers an area of about 100 square meters, and the smallest fermentation site also needs 100 square meters. The entire factory area also includes warehouses and pre-treatment warehouses, which must be included in the site planning.

When choosing a factory area, it is better to be large than to be small. If the site is large enough, you only need to add other equipment when expanding your business. If the site you choose is relatively small, you will have to select another venue.

cost of machine for making organic manure

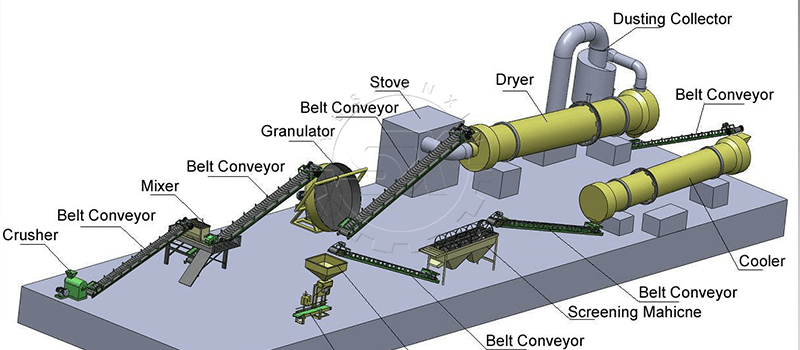

The cost of machines in organic fertilizer production lines mainly includes composting machines and granulating machines. Also, to make the process go smoothly, other auxiliary equipment is also essential, such as a fertilizer mixing machine, crusher, screening machine, dryer, cooler, and packing machine.

MFP factory manufactures three types of groove compost turners: groove type composting machines, chain-plate composting machines, and wheel type compost turners.

Windrow composting costs you less compared to the other two composting methods. In this method, you need to make long piles of your farm manure on the smooth ground and then turn them frequently with self-propelled composting machines. It can save you money in constructing grooves. However, it also requires a vast area of the factory.

In vessel composting machine is costly for its excellent fermenting capacity, which can ferment compost in 10 hours (then you need to wait for the aging process). Moreover, it has a capacity of 5-150m³.

As for granulation, there are also two granulation organic fertilizer production lines. One is the wet granulation line and the other is the dry granulation line. The latter granulation method doesn’t need a dryer or cooler and can be packed directly. But it can only apply to small-scale granulation lines (1-3tph). While the wet granulation method can produce fertilizer pellets on large scales. At the same time, to meet the packing and storing requirement, the moisture of pellets should be under 20%. Thus, drying machines are essential.

To achieve continuous production, fertilizer belt conveyors are necessary. You can use them to transport materials without workers. Furthermore, a crusher can turn manure into fine powder and a horizontal mixer can fully blend raw materials. If there are strict environmental protection requirements in your area, you can use a dust collector to reduce dust pollution.

The cost of machines for making organic manure is determined by your factory capacity. If you’re planning to make organic fertilizer, we will provide you with a free quotation and design. Please feel free to contact us.

What Is the Profit Margin of Organic Fertilizers?

According to a report by Fortune Business Insights, the global organic fertilizer market size will present a remarkable growth trajectory in 2023. Compared with synthetic fertilizer which is detrimental to the environment, organic manure fertilizer has aroused wide interest for its natural nutrients. Moreover, startups in organic fertilizer now appeal to venture capitalists. The organic fertilizers market is thriving with the promotion of sustainable agriculture by national governments. Because organic fertilizer can not only improve the soil but also can help to boost crop yields.

Therefore, if you own a poultry or livestock farm, making organic fertilizer can bring you additional profits. Excluding the construction of rainproof steel structure greenhouses, organic fertilizer raw materials, and workers’ wages, you can make the money back in 4 to 6 months, and you can get the profit in half a year. The return is generous and the profit is considerable. In the next paragraphs, MFP factory will introduce you the whole set of prodcution line. After reading it, you will know how to turn organic manure into fertilizer in a convenient and fast way.

organic fertilizer production line cost

At last, you may wonder how does it cost to set up a fertilizer factory? We can give you a rough estimation about 3tph and 5tph organic fertilizer production line cost.

A 3-ton-per-hour granulation production line will cost you about 140,000 $. And it needs 3,000 square meters area. While if you plan to make organic fertilizer powder, it will cost you less money. A 5-ton-per-hour powder production line will cost you 45,000 $. And it needs about 1,500 square meters of factory land. Of course, workers’ wages and lease land should also be included.

MFP company can give you the best advice about the figuration of plants and installation tutorials. Meanwhile, MFP is a well-established manufacturing company and renowned both at home and abroad.