What Is Batch Processing In Fertilizer Industry?

The batching system, which is separated into an automatic dynamic batching system and static batching system, is used in the first step of fertilizer production. The batching system precisely controls the fertilizer formula ratio.

According to the kind of fertilizer formula, the automatic batching system can increase or reduce the number of silos, and the automatic control system controls the number of raw materials in the silos to control the fertilizer formula.

The automatic batching system is a device for the automatic batching of additives and premixed raw materials. It solves the low efficiency of the manual weighing as well as the phenomenon of incorrect weighing.

What Is A Batching System?

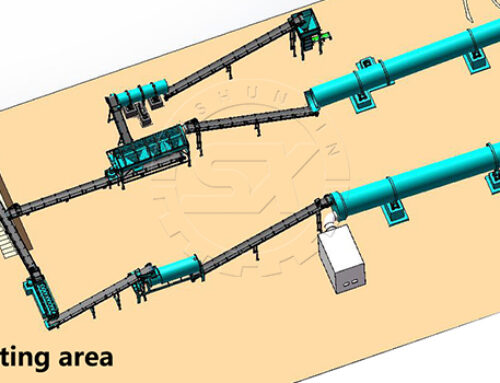

The automatic batching system is mainly composed of feeding system, weighing device, silo and conveying belt. The static batching system has the speed of dynamic batching and the accuracy of static batching (0.2%) at the same time.

The automatic batching machine is mainly suitable for mixing, batching, and feeding 3-8 kinds of materials. The machine adopts a computer scale for automatic control and uses a pneumatic gate to control the main silo for quantitative feeding, and the materials are mixed by the mixing silo and sent out automatically by the belt conveyor.

What Are Characteristics Of Batching Systems?

This machine has the advantages of simple operation, high precision of batching, the material ratio can be adjusted at will, energy saving, easy to install and can be moved, etc.

It is convenient and fast to transport raw materials because you don’t need a feeding elevator. What’s more, it requires fewer feeding workers.

The output is 8~30t per hour, with various specifications for workers to choose from. Therefore, it can fully solve the contradiction of BB fertilizer due to the seasonal concentration of material.

Small space occupation: the batching system is placed under, and it has a small footprint and low height.

High precision: batching and packing are electronically weighed, with strict control of proportioning.

Good process: drum type mixing, single bucket lifting, not to damage the original particle shape of the material, more to prevent the mixed finished product from segregation again.

Easy to clean up: the production line does not have any dead corners for hiding materials, and it is convenient and simple to clean up after stopping.

Easy management: the main control room of the production line then can monitor the operation status of each component of equipment.

Strong adaptability: suitable for various harsh site environments, including the northern alpine region and the southern humid region.

Leave A Comment