Large Scale Compost Machines Help You Make Commercial Compost

Compost, I bet you are familiar with this word. It is organic material made from organic solid wastes, such as animal manure or agricultural waste.

But do you know that you can make your own commercial compost? Writers in MFP factory came across a wonderful post from ECO FARMING DAILY, which tells how the author, Malcolm Beck, began to make commercial compost by himself. Malcolm started Garden-Ville, a composting company, and has been an organic farmer all his life. Particularly in south-central Texas, he was well-known.

His Garden-Ville enterprise has expanded from a compost pile on his family farm to a multi-million-yard operation in just a few years.

Now, follow me to learn more about how his compost business works.

How Malcolm went on his compost journey?

“Our farm was more of a hobby than a necessity,” said Malcolm.

He used to work on the railway. And he raised vegetables as a hobby. So, he gathered cow dung from his and his neighbor’s farms to make compost piles.

One day, a friend visited his farm and bought some compost at last (forty dollars for four yards). Then, an idea struck him that it would be a good option to sell compost.

“Every living thing will sooner or later die. When it dies, it is going to rot whether you want it to or not. Composting is the art of working with the decay process in an economical way.” Malclom said.

However, before setting up a large-scale composting factory, you need to make sure it is profitable.

It would be best if you considered all the costs, such as raw materials prize, and distance from your composting factory to farms. Now let’s learn more about it.

First step to start a commercial compost business: choose a site

Be careful to choose a site because the highly unpleasant smell may piss neighbors off. If you don’t want to receive a complaint, ensuring your site away from people’s houses.

Next, it would be better if there were many big trees around the site. Because trees can help prevent noise and dust. At the same time, it will reduce the bad smell.

second step: purchasing high-quality compost turners

Malcolm said that he started to make compost in the early 70s. His method is to make windrows, but then he realized he just dried them out.

Moreover, it is hard to recover pile moisture. Inadequate moisture in the windrows is why most operators failed in making compost.

Through uncountable experience, he believed that the C/N ratio and moisture are key factor to success.

Tips: it is around 30 or 35 to 1, or possibly higher. And one must turn the piles at least 4 times at appropriate moisture(50%-60%).

Why high quality commercial composting machines are so necessary?

To ensure the pile is fluffy, you must use commercial composting machines. If raw materials like cow manure are caked up in big chunks, you have to break them up. Besides, you have to make sure the moisture of the piles. Commercial composting machines can solve your problems.

For example, crawler-type compost turner can break up big chunks in the compost because there are steel drums with paddles on the beam.

Moreover, there are water pipes in the front of the machine. So you can add additional water to control moisture at any time.

Next, there’re bottles, plastics, and other garbage, so you have to screen them out first. A rotary screener can help you with this.

Get a Quote

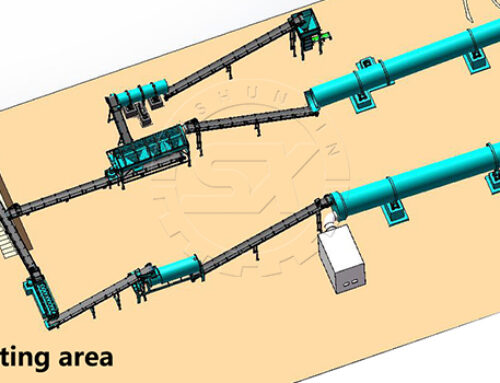

Besides composting machine, MFP factory also sells granulator machines and other auxiliary equipment to help continuous fertilizer production operation.

Our machines can not only accomodate organic fertilizer production line, but compound ferilizer production line as well.

If you intend to make compost, welcome to send an inquiry to us!

Leave A Comment