Organic Powder Fertilizer Production Line

The organic fertilizer powder production line is easy to operate and requires low investment. Thus, it is recommended for small-scale farms and fertilizer factory startups. In general, 2 or 3 people can operate the whole production.

Poultry and livestock manure are good fertilizers for plants and crops. Similarly, it is natural and without chemical additives. Thus, making organic fertilizer is not only profitable but also environmentally friendly.

Powder Organic Fertilizer Raw Materials

Much organic waste and manure can be raw materials. No matter you own a farm or collect city sludge, you can assemble this production line. The video on the right side is the production line of making powder organic fertilizer (not includes the composting process).

Follows are other raw materials that can produce organic fertilizers.

Powder Organic Fertilizer Manufacturing Process

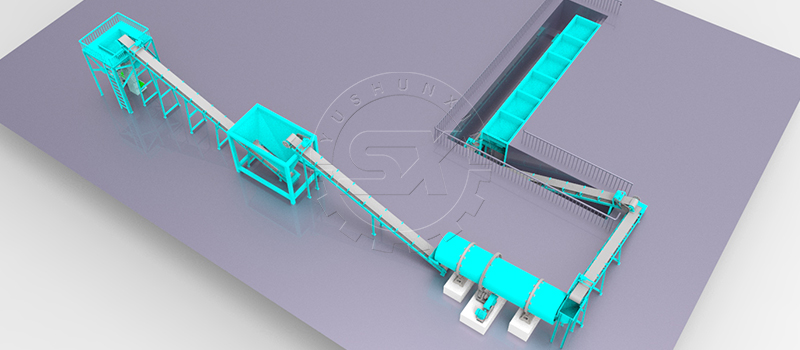

There are two steps in organic fertilizer powder production line. Pre-treatment and powder processing part. After the raw material is fermented, the organic waste contains about 30% moisture. Then, you need to crush the compost to get a fine powder.

The last step is to convey the finished product by belt conveyor to the finished product silo. With the computerized quantitative packaging system, you can pack them in bags.

The video on the right side is a whole powder organic fertilizer production line installation on site. Our client ordered a 50,000 tons per year fertilizer machines. We customize every fertilizer machines according to his required capacity.

How to make organic compost?

Groove-type Compost Turner

First of all, add the appropriate amount of straw powder to the organic manure. The amount of straw powder depends on the water content of the manure. In general, 45% moisture is good for making compost(get a hold of manure, you can feel the moisture but the water does not drip ). Then add fermentation microbes to the compost. For groove type compost turners, you can directly add microbes in the grooves. While for crawler type compost turners, you can add them to the windrow compost. In general, the compost will heat up in two days and will become odorless in four days. On the second day of composting, it will reach 60-80°C(temperature varies as seasons), and a number of bacteria will be killed. In summer, the compost can be well fermented in 10 days.

how to crush the organic compost?

Compost Crush Machine

You need to use a semi-wet crusher to crush the compost into fine powder to ensure the homogenous material. This machine can crush compost into 50 mesh and can reach 5 tons per hour. More importantly, it has a compact structure and less space.

How to screen unqualified products?

Screening Machine Made by MFP Factory

It is commonly used equipment in organic fertilizer production, mainly for the separation of products and return materials. At the same time, it also can realize the classification of finished products. The rotary screening machine adopts a combined screen and a fixed screen. Moreover, it has characteristics of screening efficiency, low noise, less dust, long service life, and small maintenance. Also, it is easy to repair and replace.

How to pack your powder organic manure automatically?

Fertilizer Bagging Machine

The packaging machine has a small footprint. Meanwhile, it is flexible and convenient for installation. You can adjust its speed, and its feeding speed can be set freely. Environmental protection operation, closed internal circulation systems, effectively prevent dust, and improve the working environment.

Other Equipment In Powder Organic Production Line

Powder organic fertilizer production line is suitable for your own farm use or neighborhood sales. So you can choose the low-cost processing equipment which also can assemble small-scale production.

A small production line may cost you about $30,000-$50,000(about 3-5 tons per hour), while a larger capacity may cost you about $60,000-$100,000(about 10-20 tons per hour).