Pan Granulator

The pan granulator, also called disc granulator, or disc pelletizer, is one of the main equipment for making compound fertilizer(bb fertilizer and NPK fertilizer), organic fertilizer and inorganic fertilizer.

The organic fertilizer disc granulator adopts an overall arc structure. By this structural design, its granulating rate can reach more than 93%. Additionally, there are three outlets on a pan granulator, which is convenient for intermittent production operations. In this way, it can greatly reduces labor intensity and improves efficiency in your fertilizer production line.

What Is The Working Principles Of Pan Granulator?

The pan granulator is a machine that combines the raw materials with water and rotates them in a circular pan. After adding water to the powder, a thin layer of water is formed on the surface of the particles, creating a spherical core due to the surface tension of the water. This core is then gradually shaped into granules through the rotation of the disc, and the granules roll towards the edge under the influence of centrifugal force.

How does a pan granulator work?

In a disc granulator, the balled materials are continuously discharged from the disk and new materials are added into the feeding tray, repeating the process until the powdery materials become spherical products.

The particles form spherical particles by agglomeration, and as they increase in size, they move up to the circular disc in rotation. Finally they roll to the edge. The small particles initially roll near the bottom edge of the circular disc.

During the rolling granulation process, due to the influence of gravity, the spherical particles make circular motion.

Klatt’s experiments in 1958 showed that the finer the solid, the more uniform the liquid that is sprinkled in, the better the granulation. The smaller the droplets of material, the smaller the diameter of the granules, and the lower yield. Conversely, the denser the droplets, the more granules, and the higher the yield. Besides, the feed rate can control the granulation temperature.

How to Choose A Good-quality Pan Granulator?

A good pan granulator should be a high-quality design, because each part of disc granulators will influence its effect.

Therefore, when you choose a pan granulator, you’d better take the following factors into consideration.

How to Operate the Disc Pelletizer?

Disc pelletizers are easy to operate, but there’s a few key points you need to bear in mind. The first thing is that the angle of disc granulators will determine the size of finished granules. For your convenience, our pelletizer disc setting adopts hand wheel adjustments, so you can adjust the angle of your disc granulator without using any tools.

Here’s instructions about how to make pellets by disc pelletizers.

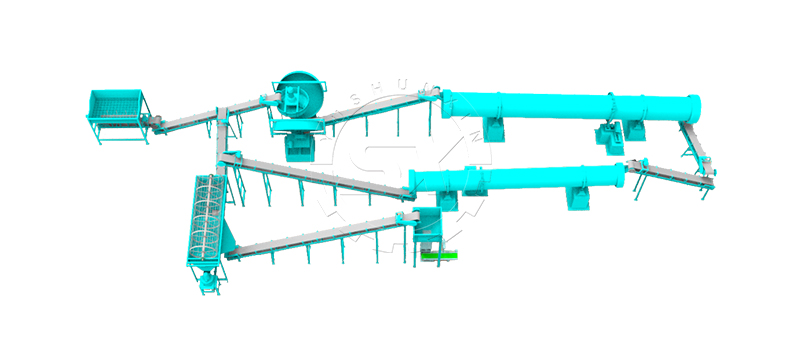

Fertilizer Pan Granulation Line

Fertilizer Pan Granulation Line

How to Choose A Pan Granular Machine for Your Business?

To choose a pan granulator suitable for your business, you need consider its diameter, size, height and capacity. In general, the diameter of the disc determines the capacity. For example, a pan granulator with a diameter of 2m can produce about 1.3t granules per hour, which means you can reach about 2000t every year. As such, a disc granulator with a diameter of 2.5 meters can produce about 1.8t granules per hour, that can reach 3000t productivity per year. We have different parameters for you to choose from.

To sum up, when purchasing a pan granulator, you’d better read its specification carefully and choose one that lies with your business.

How Does Rotary Speed Influence Pan Granulating Rate?

According to studies, rotary speed greatly determines the balling rate. If the rotary speed is too high, the material will stick to the edge of the plate, affecting the ball-forming rate.

As it mentioned above, the height of pan granulators will affect the size of finished granules. Another important is the rotatory speed. After you make sure of the height of the granulator, you should observe the state of the materials. Only the height and rotatory speed are proper, can it produces granules of appropriate size and hardness.

Practical Ways To Increase Productivity Of Disc Granulators

Control the moisture content of the particles to be around 30%-28%. If the moisture content is too low, it is difficult to form balls and the yield is low. If the moisture content is too high, the balls are large and the surface of the balls is sticky, easily clogging the screen surface. Only if the moisture content is appropriate, can it reaches a high granulating rate.

But you may wonder how to know the moisture is moderate. Here’s a simple way. Grab a handful of finished products from the disc granulator, if your hand can form a ball, touch it gently with your finger and then release it. In this way, there are more granules, and it is not easy to clog the equipment.

Warranty And After-Sales Service Offered For Our Disc Granulator

Whole Year Warranty When you Buy our pan granulator

We offer a comprehensive warranty for our product. As a renowned pan granulator supplier, we have fertilizer equipment experts who can help you with the installation. Whether it’s a minor repair or a major overhaul, we can ensure that your disc granulator operates at peak performance.

After-Sales Service for Disc Granulator

No matter if you encounter troubles with the installation or granulating process, our team of experienced technicians is here to help. Simply contact us, and we will assist you in resolving any problems you may have.

We are dedicated to providing our customers with the best after-sales support. If you have any questions or concerns, please don’t hesitate to contact us.